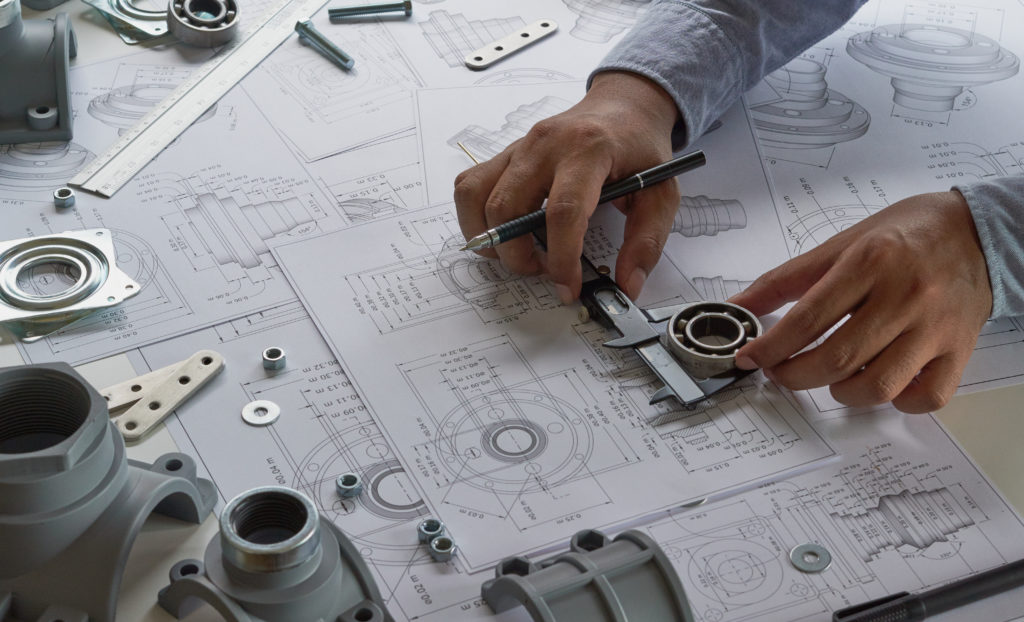

Castings – An Effective Alternative to Fabricated Products

Casting technologies have progressed significantly in recent years, advancing the capability to produce castings with increasingly complex geometries. In addition, these technological developments have promoted the use of an extended range of alloys, as well as expand the range of processing conditions to optimize the final properties of the material for the application.

The concurrent application of advanced engineering design practices and tools with the right casting processes and materials, results in an optimally designed component. Focusing on what best suits the needs of the customer in terms of fit, form, and function is important to achieve quality levels at a competitive cost level.

The potential advantage which modern cast products can offer over fabricated counterparts can be:

- Higher quality (reduced stress from welding, better machinability, increased consistency, and strength)

- Cost Savings (by reducing processes and production time)

It is important to reiterate that optimal performance is achieved not only through design procedures, but also through simultaneous/coordinated consideration of the process-dependent properties the material can offer.

Selecting the correct material must consider process routes and technologies required to cast the material into the component design geometry. Subsequent thermal treatments and interactions with the cast structure and condition are also necessary factors to include in the process stream.

A coordinated effort is required between the designer and the process engineer. Thus, the production of cast components satisfying “the best of all considerations” requires an optimal mix of complex and multi-faceted disciplines. Successful transitions to cast products continue to increase in today’s world of continuous improvement.

In summary, the considerations which go into the production of cast products must consider the following fields:

- Engineering and Design

- Materials Selection

- Process requirements to meet the needs of the above

Accucam offers Fabrication to Casting conversion solutions for a variety of components delivering reduced weights, optimum design, and decreased costs for OEM customers.

Are you interested in value-add technical support and cost savings? Have you considered a fabrication to cast conversion? Contact us today to get in touch with one of our technical team members to discuss your needs!

Call Manufacturing

Call Manufacturing