Three Key Quotation Factors

Today, in many industries, companies encounter pressure from consumers to introduce a product at the optimal price point and with stringent delivery demands and superior quality performance. Strong dependence on the price point of a product is overshadowed by the delivery requirements and product quality expectations. The three factors of cost, delivery and quality are key to optimization and evaluation during the formal quoting process. By optimizing these factors, the standard practice of preparing quotations has a sustainable effect on customers.

At Accucam Machining, we encounter a variety of quotation opportunities:

- Design development and collaboration

- Quote to print

- Castings with and without machining

- Machining of bar material products

- Welded assembly products

- Assembly manufacturing

Accurate quoting requires specific details such as:

- Design drawings

- Material specifications

- Customer product samples

- Estimated annual usage (EAU)

- Project timeline

- End use application

- Target cost

- Supply chain management

- Production capacity

- Quality specifications

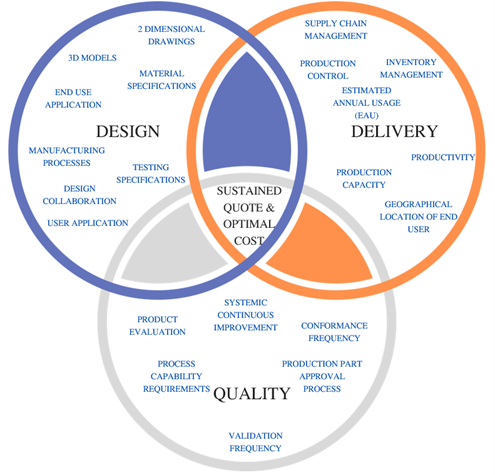

A visual representation using the Venn diagram below includes requirements centered around the focal point of preparing a sustained quote with optimal cost parameters.

Each of the requirements within the circles of the diagram has a direct impact on the price magnitude presented in the quote. When requirements are added or removed the optimal cost changes, which may reduce the accuracy of product price, demand requirements and quality output. For example, when examining the diagram for the geographical location of the end user in the delivery circle, there could be an increase in logistics costs that impacts the price. If testing specifications are removed from the design circle, parts may prematurely fail, though lower overall cost in the RFQ may be achieved. When too many requirements are specified, causing parts to be over engineered, the product will be overpriced and not within program budgetary requirements.

Customers and suppliers have a significant role to play in ensuring that the necessary requirements are assigned to product design, procurement, and quality assurance during the RFQ initial stage. If too many or too few requirements are assigned, the market may not tolerate an overpriced, high-quality product or a low-cost product of substandard quality. Having clear project details is a vital part of the quote process to ensure that we are at the focal point of a well-prepared sustained quote with the optimal cost.

Learn more about working with Accucam to develop an optimal quote for your castings and machining needs by clicking here.

Call Manufacturing

Call Manufacturing