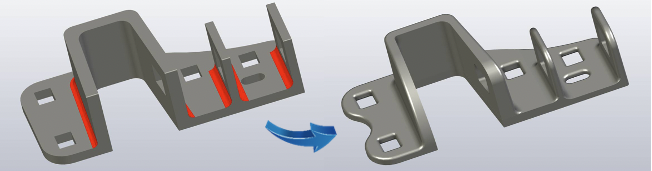

Conversion of a Fabricated Latch to a Casting

We recently redesigned a small, welded latch assembly into a casting. The conversion to a casting saved the customer more than 30% on original fabrication costs, 15% in overall mass savings and eliminated four sub-assembly parts to track, source, and weld.

Fabrication to casting process

Previously, the latch base was a welded assembly of four different components, each cut from plate steel. Three different plate thicknesses were required and the component layout resulted in substantial leftover scrap plate. The overhead cost associated with the additional sourcing, processing and inventory management of the individual steel components were evident.

The welding required each piece to be fixtured in place to maintain alignment during the process. While the volumes did not warrant robotic welding, a manual welder completed the fixturing and hand welding of the pieces. The fluctuating thermal inputs from welding, fixture alignment repetition and varying amounts of weld deposition contributed to substantial process variation & costly, repetitive quality inspections.

The variables above contributed to making this welded component a strong candidate for conversion to a single steel cast part. During casting design several improvements were made to the component that leveraged some of the advantages of casting, including:

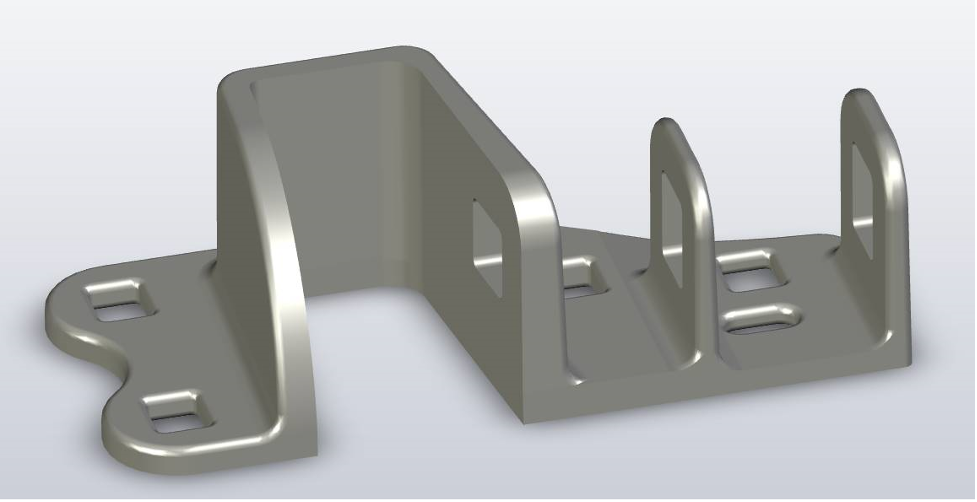

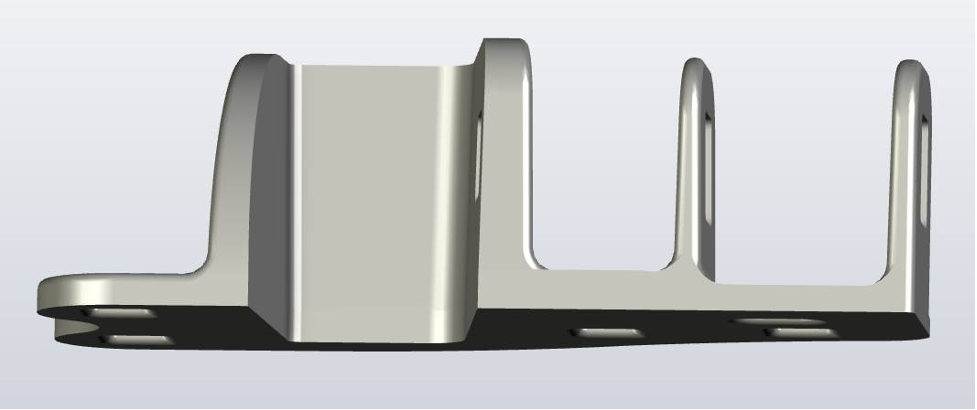

- Mass reduction: The casting design made it easy to remove excess material—material that was not required for the function or strength of the part.

- Material thickness optimization: Wall thickness could be altered in every region of the casting, depending on strength and durability requirements.

- In total, approximately 500 mm of welding was eliminated and the base part count was reduced to one. With the shape flexibility provided by casting, the mass decreased from 4.49 kg to 3.82 kg – a 15% reduction. On top of all these benefits, the cost to the customer was 30% less.

Less cost, less complexity, more robust parts – contact Accucam today for your fabrication to casting conversion projects!

Call Manufacturing

Call Manufacturing