Accucam Machining: World-Class Metal Component-Part Supplier to OEMs

Accucam Machining started in 1987 as a small machine shop in Cambridge, Ontario, Canada. Today, operating out of two facilities in Cambridge and one in Qingdao, China, we are a trusted Metal component-part supplier to global heavy equipment OEMs—in an impressive range of industries.

Our story of success is rooted visionary thinking, technical acumen—and the pursuit of excellence.

As a wholly owned, full-service (machining, castings, forgings, weldments, stampings, assemblies, paint, and warehousing) OEM partner, Accucam combines advanced capabilities in design, engineering and precision manufacturing with global supply chain management solutions. Integrating these comprehensive offerings generates synergistic benefits that have helped us forge deep, long-standing relationships with our partners around the world.

Design, Engineering and Precision Manufacturing

As an industry leader, Accucam Machining has refined its process to deliver exceptional value to our customers from start to finish. We offer support for:

Product Design

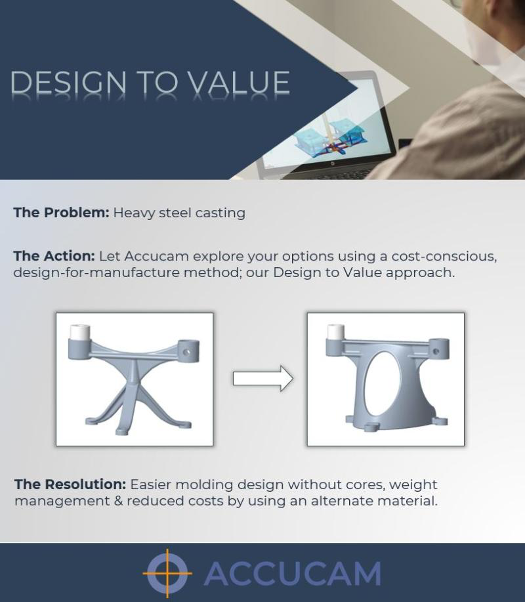

Our philosophy is to provide you with a solution along the whole life of your product, starting with the development stage. This is an expression of our Design to Value approach whereby we collaborate with you to develop your product concept into a cost-effective, manufacturing-friendly design.

We assist in material and manufacturing process selection (investment casting, sand casting, die casting and forging), and then apply best-practice design principles to create a best-cost solution for your design. Products can range from small (<0.01kg) to large (>500 kg) castings, with annual volumes from 500 up to 275,000 pieces.

Engineering

The physics involved in filling a mold and solidifying the molten metal are complex. We use industry leading Magmasoft software to conduct casting simulations that are vital to defect prevention. Magmasoft is an essential tool in the development of new cast components as it optimizes yield and reduces scrap, even before cutting tooling to make parts.

Spending the time to virtually develop a gating and riser system for a casting repays itself many times over in the time and cost saved by making physical trials.

Prototyping and Testing

Accucam provides multiple options for prototyping and validation. Working with our foundry and forging supply partners, we supply initial parts using rapid prototyping techniques or samples using production-intent processes and tooling – to match your cost and timing goals as closely as possible. Component validation is a combination of in-house and procured services: chemical analysis, microstructural analysis, tensile testing, salt spray corrosion testing, magnetic particle inspection, x-ray, ultrasound, and dimensional verification (coordinate measuring machine, hard gauges, 3D scanning).

Precision Manufacturing

At the conclusion of a successful Design to Value collaboration, Accucam is positioned to supply a finished component with any number of finishing steps. Our network of value and precision sources allows us to create the best value machined casting or forging for your application.

We then manage the remainder of the component value chain, so you only need one point of contact. Finishing services include heat treatment, assembly, welding, brazing, cleaning, plating, painting, coating, inspection, and shipping logistics. We can do it all for you.

Global Supply Chain Management for OEMs

Our global scope and partnerships enable us to streamline our Continuity™ system of global supply chain management. From Forecasting and Demand Planning to Logistics Management, Continuity™ ensures confidence in providing optimal product quality, delivery, and supply. Continuity™ also allows our partners to tap into outsourced prices while dealing with North American customer service representatives and enhanced supply chain resiliency.

Accucam Machining’s resilient global supply chain management system supports OEMs with:

To discuss your upcoming engineering and manufacturing project, or to learn more about optimizing your supply chain while reducing costs, please contact Accucam Machining.

Call Manufacturing

Call Manufacturing