Each of our OEM customers has unique needs. Our strategic services are designed to meet them – collectively or selectively.

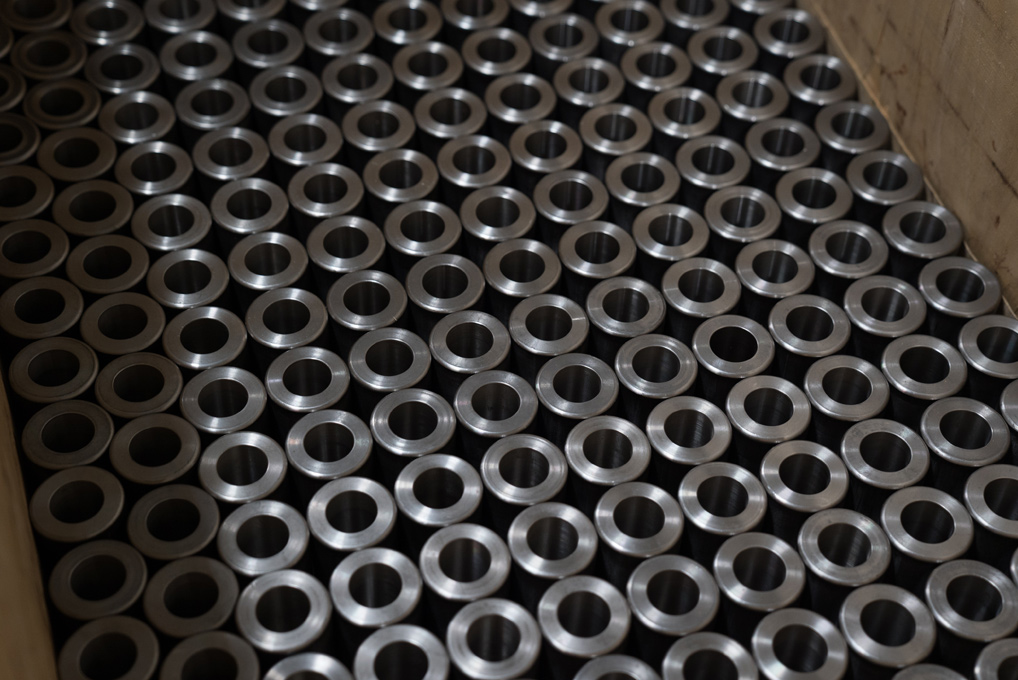

Accucam is a strategic partner for OEM customers who may need some or all of our specialized, technical services in manufacturing custom machined components, assemblies and castings. Our customers can choose what meets their current need and then we get to work to save them costs, improve efficiencies and deliver world-class components.

Our global scope and partnerships enable us to streamline our Continuity™ system of global supply chain management. From Forecasting & Demand Planning to Logistics Management, Continuity™ ensures confidence in providing optimal product quality, delivery and supply.

-

Design, Engineering & Manufacturing

Accucam has a technical team capable of creating and solving complex design, engineering and manufacturing solutions.

Learn More

-

Supply Chain Management

Our start to finish, a sophisticated supply chain management system provides our OEM customers with confidence and value.

Learn More

Call Manufacturing

Call Manufacturing